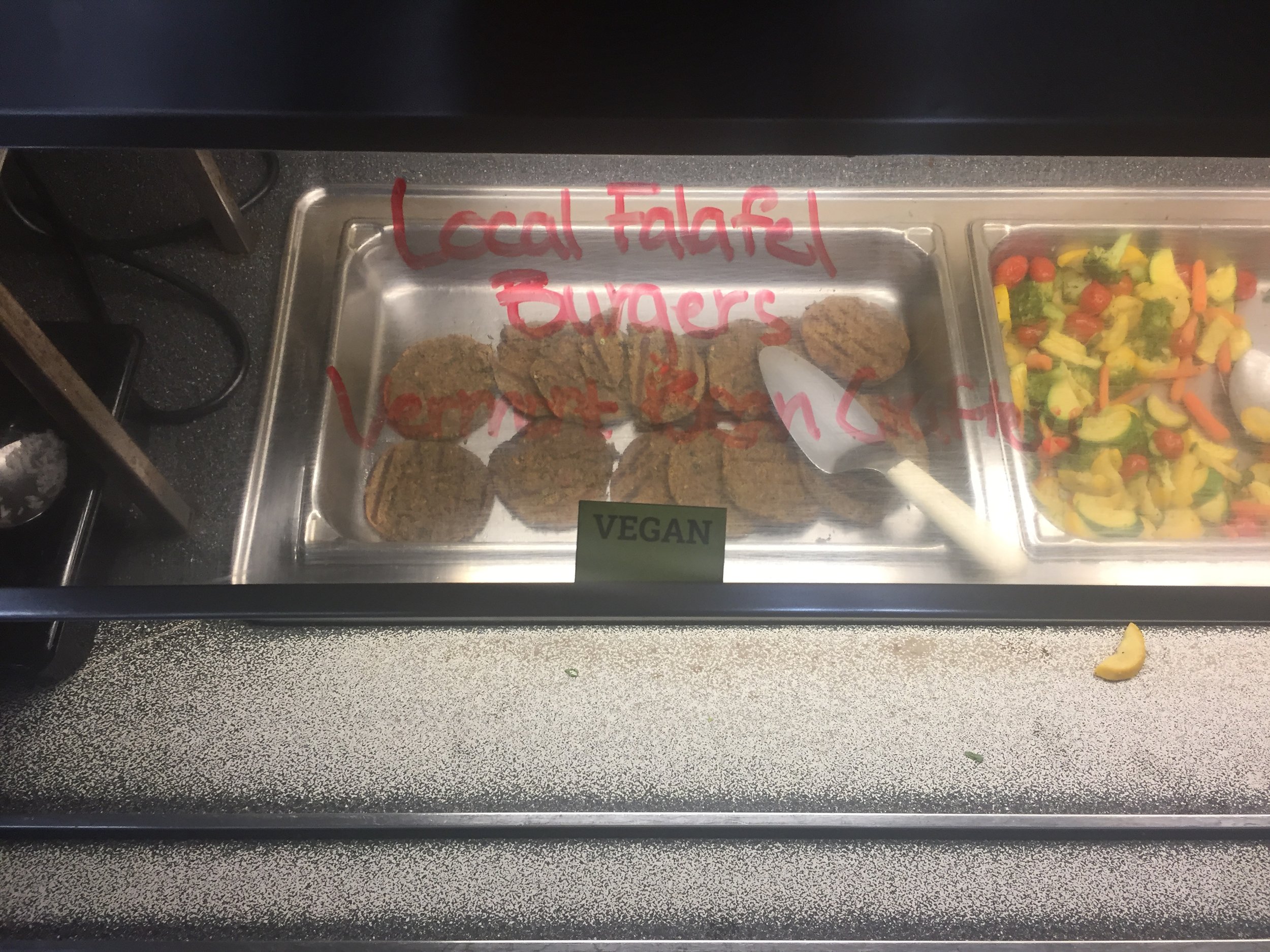

Food Connects offered many regional products from regional producers, including:

Tom Brewton, Food Connects Institutional Sales Associate, tabled at the event during lunch hours and was able to share with students and faculty about the regional products featured on the menu. Laura Carbonneau, Food Connects Marketing and Outreach Manager and NMH alumnae, joined students in the classroom, speaking about the Farm Bill, climate resiliency, food, and food systems. The response from students in the dining hall and the classroom was enthusiastic and engaged—lots of “yums.”

Deerfield Academy (DA), located in Deerfield, MA, is another boarding school for high school students in the Pioneer Valley. DA is proud to boast a Farm Team, a group of students who help out at two local farms with harvesting and garlic preparation projects. Working with DA for the first time this school year, Food Connects has delivered various products, including strip loins from Big Picture Beef and burger patties from Robie Farm.

Eaglebrook School is a 6th through 9th grade all-boys boarding and day school also located in Deerfield, MA. This year alone, the school has purchased 3,672 pounds of ground beef from both Big Picture Beef and Boyden Beef.

Public Schools

Food Connects has a history of working with public schools throughout Vermont and New Hampshire, providing high-quality, regionally-sourced foods. The Food Connects team takes pride in extending those same products and services to public schools throughout Massachusetts’s Pioneer Valley.

Greta Shwachman, Food Service Director for Greenfield Public Schools (GPS), is passionate about integrating local products into her menus. This is no surprise, as she was previously the Farm to School Program Coordinator for the Chicopee Public Schools. Her passion for Farm to School has made adding regionally sourced foods to her menu seamless.

“Institutions like K-12 schools hold a lot of purchasing power,” says Greta. “I prioritize buying regionally-sourced foods to ensure that this power is used to support the local food economy. I enjoy the opportunity to meet farmers and producers, and help local food businesses grow and scale to have more success in the institutional market.”

Food Connects has supplied the GPS, which consists of 6 different schools, with ground beef from Big Picture Beef, bulk yogurt from Narragansett Creamery, and granola from True North Granola Company. And not just food but also promotional marketing materials, so students can connect with their food and the farmers.

“I believe that students should know where their food comes from,” says Greta. “And I enjoy working with Food Connects because they understand the importance of putting a face and a name with a product. I have appreciated the signage they have sent us, which includes background on the producer, and even the number of miles the product traveled to reach our cafeterias.”

Earlier this year, Tom met with Michael Onorato, Food Service Director of the Pioneer Valley Regional School District (PVRSD). Coincidentally, Michael was already familiar with Food Connects—he was previously the Food Service Director for Conval Regional School District, another school district Food Connects serves. To date, Food Connects has supplied the PVRSD with various products, including apples, potatoes, carrots, and eggs.

Food Connects is also working with Massachusetts Farm to School, whose mission is to “strengthen local farms and fisheries and promote healthy communities by increasing local food purchasing and education at schools.” The organization, aligned with both the Vermont and New Hampshire Farm to School programs, serves as a vital lifeline for Massachusetts schools to access support, curriculum, and other resources to develop Farm to School programming.

Food Connects will participate in the Local Food Networking Session on Thursday, June 16, from 3:00 to 4:30 PM in Greenfield at the John Olver Transit Center. This event will be a spring get-together for K-12 school nutrition professionals in Franklin County. The event will include vendor displays, sampling, presentations, and discussions. And while the focus will be on local food procurement, there will be discussions on other topics. The event is being co-organized by the Partnership for Youth at FRCOG (Franklin Regional Council of Governments), Greenfield Public Schools, and Western Mass Food Processing Center at the Franklin County Community Development Corporation. If you are a school nutrition professional and want to learn more, you can register for the event today.

If you are a food service director, work in a school, and would like to integrate more local foods into your menus, Food Connects would love to support you! At this time, their customer routes go from Brattleboro, VT, down I-91 as far south as Northampton, MA. Know that our routes are quickly expanding so we would be happy to hear from you even if you don’t fall within our existing geographic reach in MA. Please reach out to their sales team at sales@foodconnects.org.